An MEng project may be completed in lieu of three half-courses. If you are interested in a project listed here, contact the professor directly. If you don’t see a project that is of interest to you, contact any of our other professors to discuss topics. Some MSE faculty members may have projects not yet listed here.

If you decide to complete a project, submit an MEng Course + Project Enrollment form to mse.grad@utoronto.ca. Then enroll in MSE3000Y. Note that Safety Training is required and will be provided.

Upon completion of your project, you must prepare an MEng project report for your project advisor who evaluates the report. CR (credit) or NCR (no credit) will be awarded.

Co-Supervised MEng Projects

The following MEng projects are collaboratively supervised by experts across different disciplines, offering students a unique opportunity to work on interdisciplinary research:

- Corrosion of steels by hygroscopic salts

Co-supervised by Prof. Jane Howe and Prof. Nicolas DeMartini (Chemical Engineering) - Early stages of copper corrosion for nuclear waste storage applications

Co-supervised by Prof. Jane Howe and Prof. Uwe Erb - High-throughput scanning electron microscopy

Co-supervised by Prof. Jane Howe and Prof. Jason Hattrick-Simpers - Liquid electron microscopy of micro and nanobubbles for medical applications

Co-supervised by Prof. Jane Howe and Prof. Naomi Matsuura

MEng Projects by Research Groups

Nanotechnology, Molecular Imaging & Systems Biology Group

Naomi Matsuura, Associate Professor

E: naomi.matsuura@utoronto.ca

Minimizing drug degradation during anti-cancer drug carrier synthesis

Potent, hydrophobic chemotherapy drugs are employed to treat cancer patients. These drugs can be directly loaded into ultrasound-responsive bubble carriers for triggered release near the tumour site. However, these drugs can degrade during their incorporation into the carrier because of the high temperature and pH of the synthesis process.

It is hypothesized that the addition of a so-called degradation inhibitor can significantly minimize the extent of degradation of the chemotherapeutic drug. The study therefore will examine the impact of drug degradation during the formulation process of ultrasound-stimulated bubble-based drug carriers using citric acid as a degradation inhibitor. The following objectives will be pursued: (1) assess the drug degradation and in vitro stability of drug-loaded bubbles following the incorporation of citric acid at three different acidic pH values at a fixed heating temperature and duration; (2) examine the physical characteristics of precursor drug-loaded droplets with and without citric acid; and (3) evaluate the in vitro cytotoxicity of drug-loaded bubbles synthesized with citric acid at the optimized pH on murine mammary breast cancer cells.

Development of a novel biodegradable embolic agent for genicular artery embolization in osteoarthritic pain treatment

Osteoarthritis (OA) affects over 500 million people worldwide, with pain as the most prominent symptom. Many OA patients find themselves in a treatment gap, where non-invasive therapies have failed, but they are ineligible for knee replacement surgery. Genicular artery embolization (GAE) has emerged as a promising intervention for treating moderate OA that is refractory to conservative therapies yet not severe enough for joint replacement. This minimally invasive procedure selectively embolizes abnormal neovasculature, alleviating OA pain and inflammation by targeting the aberrant angiogenesis and sensory neoinnervation associated with chronic inflammation, while preserving overall knee blood flow.

Despite promising clinical outcomes, the embolic agents currently used for GAE are suboptimal, suffering from issues such as non-degradability or unpredictable occlusion and degradation profiles. Thus, there is a clear clinical need for a degradable microsphere embolic agent specifically designed for GAE, with a predictable occlusion and degradation timeline tailored to OA treatment. This project aims to optimize the fabrication of a biodegradable embolic agent recently developed in our lab for GAE applications and to evaluate its in vitro performance. The research will focus on assessing the mechanical and degradation properties of the embolic agent and its occlusion and recanalization behavior in an in vitro embolization model. More specifically, we are interested in characterizing the mechanical properties of embolic particles and altered occlusion behavior as a function of the degradation time.

Microfluidic fabrication of hyaluronic acid microspheres as biodegradable embolic agents

Endovascular embolization is a minimally invasive procedure with expanding applications in medicine. For many procedures such as the treatment of hepatocellular carcinoma, benign prostatic hyperplasia, uterine fibroids, and musculoskeletal pain, temporary embolization for a specific period is desired. Although several permanent agents are currently available, the number of commercially available degradable agents is limited. Among different classes of embolic agents, polymeric microspheres are widely used for their predictable occlusion and degradation patterns, with different applications requiring embolics of varying sizes, stiffness and occlusion periods.

Hydrogel microspheres made from hyaluronic acid (HA) holds promise for development of biodegradable embolic agents, as HA is a natural polymer found in nearly all body fluids and tissues, is biocompatible, biodegradable, and non-immunogenic. We have recently used in-emulsion crosslinking, in combination with a salt treatment technique, to fabricate HA microspheres with tunable mechanical and degradation properties. However, the current bulk synthesis approach results in microspheres with a size distribution spanning approximately 300 µm. In this project, we aim to design a microfluidic device to enable the fabrication of HA microspheres with enhanced size uniformity. Subsequently, the device design and the microsphere fabrication parameters will be optimized to achieve HA microspheres with precisely tailored properties.

Drug-eluting hyaluronic acid microspheres for embolotherapy

Although the unintended occlusion of blood vessels can lead to severe conditions such as heart attacks or strokes, the deliberate and targeted cessation of blood flow to specific tissues or organs can be therapeutically beneficial in some medical conditions. This approach, known as endovascular embolization or embolotherapy, is a minimally invasive procedure with expanding applications for treating several conditions, including arteriovenous malformation (AVM), benign and malignant tumors (e.g., hepatocellular carcinoma, uterine fibroids, benign prostatic hyperplasia, and spinal cord hemangioblastomas), and certain musculoskeletal disorders. In many cases, temporary embolization for a defined duration is preferred. While several permanent agents are commercially available, the range of degradable agents remains limited.

Our group has previously developed hyaluronic acid (HA) microspheres with tailored properties for use as degradable embolic agents. However, in specific applications, it is desired to incorporate drugs into embolic agents to create drug-eluting embolics. For instance, in chemoembolization for tumor treatment, chemotherapeutic drugs may be loaded into the embolic agents to enhance the therapeutic outcomes. This project aims to evaluate the efficacy of loading model drugs into our HA microspheres and to investigate the drug release profiles during microsphere degradation.

Interested students are encouraged to contact Professor Naomi Matsuura (naomi.matsuura@utoronto.ca). Please include your CV and a brief letter of interest.

Surface Engineering & Electrochemistry (SEE) Group

Steven Thorpe, Professor

E: steven.thorpe@utoronto.ca

Mechanical Alloying Applications in Hydrogen and Oxygen Production by Electrolysis

Amorphous metals / metallic glasses along with nanocrystalline materials have shown substantial enhancements in many properties, especially in the area of electrocatalysis of various reactions. Currently, the Surface Engineering and Electrochemistry (SEE) group is examining the fabrication and properties of Ni-base metallic glasses combining synthesis via mechanical alloying with structural analysis and electrochemistry in order to optimize their stability, and electrochemical activity in electrolysis. The long-term goal of this project is to expand and develop new mechanical alloying chemistries and their application in the area of electrolysis and water splitting reactions.

Electrolyser Design

Currently, the Surface Engineering and Electrochemistry (SEE) group is examining the design, fabrication using 3D printing, and electrochemical properties of membraneless alkaline water electrolysers. The long-term goal of this project is to take advantage of new nanocatalysts being developed within SEE in developing and optimizing the design of a novel membraneless electrolyser with respect to cell components and systems design.

Orthopaedics Biomechanics and Cartilage Research

Adele Changoor, Assistant Professor

Design of a Prototype Device for Non-invasive Measurement of Cartilage Quality

This project aims to develop a prototype device for the non-invasive evaluation of cartilage quality using electroarthrography (EAG). EAG measures the electrical signals generated by cartilage during weight-bearing activities through electrodes placed on skin surrounding the knee. The prototype will be a user-friendly device designed for clinical applications in both human and equine settings. Its development will involve tools such as additive manufacturing and SolidWorks, along with some imagination. This project is significant as it will simplify EAG measurements in the field, supporting ongoing research on using EAG to study joint injuries and osteoarthritis.

Development of a Digital Image Correlation System for Measuring Strains in the Pelvis

Hip replacement surgery successfully treats end-stage hip disorders by replacing the joint with metal and polymer parts. Around 8% of patients need revision surgery within a decade due to issues like loosening, dislocation, or infection. One solution for challenging surgical cases involves a cup-cage construct, which provides load relief until biological fixation by bone ingrowth occurs over time. Surgeons may manually modify the metal components depending on the patient’s bone quality and anatomy, however, to date there have been no biomechanical studies investigating the effects of modifying these components on the off-loading characteristics of the cage. This study aims to characterize biomechanical changes in the pelvis that result from cup-cage modification by measuring strain distributions over the pelvis during physiological loading. The student will develop and test a digital image correlation system for three-dimensional measurement of strain on bone surfaces. They will then deploy this system during biomechanical testing of cadaveric hemi-pelvises under various experimental conditions.

Understanding Non-invasive Measurements of Cartilage Quality using Data Science Strategies

Electroarthrography (EAG) is a method by which electrical signals produced by cartilage are measured non-invasively through electrodes placed on skin surrounding an articular joint, analogous to the collection of other bio-potentials such as electrocardiography. The electrical signals produced by cartilage result from the way this highly specialized tissue responds to weight bearing and are directly linked to cartilage quality. In our lab experiments on joint explants, we simulate joint loading and collect EAG measurements from 6 to 8 skin electrodes at one of 3 levels of load, then we open the joint to directly measure cartilage quality. The EAG measurements are influenced by cartilage quality as well as other factors like load level, contact area, and joint angle. This project aims to isolate the cartilage-specific component of the EAG measurement using data science strategies. The student may also participate in performing experiments as described above.

Smart and Adaptive Polymers & Composites Laboratory

Hani E. Naguib, Professor & Canada Research Chair, Smart & Functional Materials

E: naguib@mie.utoronto.ca

Development of Polymer Composites for Carbon Capture and Storage Technologies

The global shift toward climate solutions has positioned Carbon Capture and Storage (CCS) as a critical technology for reducing industrial CO₂ emissions. Polymer composites, with their lightweight nature, corrosion resistance, and design flexibility, are promising candidates for use in CCS infrastructure – including pipelines, liners, and sealing systems. This project focuses on the design, processing, and evaluation of advanced polymer composite materials specifically tailored for CCS technologies. The work will involve both material innovation and hands-on experimentation to understand how composite structures can be optimized for performance in CCS-relevant environments. As the successful candidate, you will gain experience with:

- Design of Experiments (DoE) to guide material formulation

- Compounding and mixing using twin-screw compounder

- Injection and compression molding for fabricating composite samples

- Characterization techniques including:

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Scanning Electron Microscopy (SEM)

- Rheological and mechanical testing, including Dynamic Mechanical Analysis (DMA)

- Gas permeation testing under controlled conditions to simulate CCS applications

This project offers a unique opportunity to contribute to sustainable materials development in support of clean energy and emission-reduction technologies, which will help you build a strong foundation in polymer processing, materials characterization, and applications in the energy sector.

Novel Lithium-Ion Battery Components for Enhanced Performance and Safety

Interested in taking novel materials design all the way through synthesis, characterization, and application testing? The Toronto Smart Materials & Structures (TSMART) lab is seeking motivated students to join our exciting research on novel lithium-ion battery components. Our focus is on designing and optimizing new cathodes, anodes, and separators to enhance battery performance (such as energy density, cycle life) and safety.

As a member of our team, you will engage in hands-on experimental work, including discovering and screening new materials, developing scalable fabrication methods, and studying fundamental principles. This is a unique opportunity to collaborate with an interdisciplinary team, integrating expertise from material science, chemical engineering, and mechanical engineering. There is also great potential to contribute to journal publications and patent developments.

Preferred Qualifications and Attributes:

- Knowledge of electrochemistry and chemical synthesis/handling.

- Experience with circuitry and prototyping (computer-aided design and modeling is advantageous).

- Excellent technical writing and communication skills.

- Ability to work independently and as part of a collaborative research team.

- Curious, committed, and self-motivated

If you are ready to take on this challenge and contribute to developing next-generation battery technology, we highly encourage you to apply.

Multifunctional sensors array for smart skin applications

Duration 2 to 3 terms

Design optimization of polymer nanocomposites with enhanced mechanical properties.

Polymer nanocomposites play a crucial role in automotive and aerospace industries, which often offer enhanced mechanical, thermal, electrical and gas barrier properties particularly at elevated temperatures when compared to the neat polymer. The primary objective of this project is to optimize the content and distribution of a selected nanoparticle in a thermoplastic matrix to achieve the highest dynamic and static mechanical properties. The student will learn the design of experiment, operation of state-of-the-art compounder, injection and compression molding, dynamic mechanical analyzer, creep tester, Instron tensile and compression tests and differential scanning calorimetry during the period of this project to develop the required skillset for manufacturing and analysis of composite systems in their future academic or industrial positions

Conducting Polymer Based Pressure Sensors for Electronic Skin Applications

Human skin is the largest sensory organ in our bodies allowing us to safely maneuver within our surrounding environment. This physical barrier which enables us to interact with our physical world comprises several sense receptors through which information from a physical contact transduces into electrical signals. An artificial skin, also referred to as smart skin or electronic skin (e-skin), with human-like sensory capabilities can make a significant impact on the autonomous artificial intelligence as well as surgical tools. This can be achieved by providing a sensory perception even better than their organic counterparts. In addition to force sensing as the primary function of human skin, other functionalities such as mechanical/electrical self-healing along with flexibility/stretchability are of great importance to be considered in an e-skin. The project will investigate the design and fabrication of a pressure sensor mimicking the main characteristics of natural skin, potential of using conducting polymers as piezoresistive sensors for electronic skin applications.

Development of new thermoplastic composites for applications under extreme conditions

Project Description: This project involves the characterization of the fiber-matrix interfacial properties in reinforced thermoplastic composites targeting high strength and resistance to extreme operating conditions including high temperature and pressure. The student will be involved with the manufacturing and characterization of various composite systems including single fiber pullout testing as well as analysis of the interface by scanning electron microscopy.

Primarily, the project will investigate the effectiveness of different coupling agents and additives on improving the strength of the fiber-matrix bond which are key to determine the performance of the overall composite. The student will be involved in the selection and research into various coupling agents for the relevant material systems. Primarily the project will involve single fiber pullout testing, a technique developed to specifically measure the interfacial properties. The student will be involved in the preparation and testing of the samples. Part of the project will utilize various imaging techniques, such as scanning electron microscopy, to investigate the wetting and adhesion of the fiber to the matrix. Additionally, the fiber composites will be characterized by the classification of all relevant mechanical properties including young’s modulus, yield stress, and stress-strain behaviour.

Best suited to Extended full-time students

Development of polymer composite systems with enhanced mechanical properties at elevated temperatures.

Additive manufacturing (3D printing) is revolutionizing the methods of product fabrication by providing freedom of design and a vast but growing choice of materials. This research project aims to develop novel fabrication methods and materials(polymers) with high performance and tunable properties implementing additive manufacturing and potential intelligent process development methods.

We are looking to support a highly motivated and talented MEng student for this project with the desired qualifications as follows:

- Engineering degree, preferably in Mechatronics or Mechanical engineering

- Good knowledge of engineering design and system development

- Basic knowledge of materials, manufacturing methods (preferably additive manufacturing), characterizations, and testing

- Interest in conducting both experimental and theoretical research

- Good knowledge of image processing and hands-on experience with machine learning

What we offer:

- A challenging and interesting job in a highly dynamic and multidisciplinary work environment

- The opportunity of being engaged in one of the leading areas of advanced manufacturing and contribute to the development of the next generation of materials and processes

- Analysis and evaluation of the achieved results in the team

Embedded Systems and Electronics for Medical Devices

Research Area: Medical devices, Embedded electronics, PCB

Embedded systems play a pivotal role in the design and development of modern medical devices. These specialized computer systems, integrated into the device hardware, are essential for providing advanced functionality, precision control, and reliable performance in a wide range of medical applications. In the past decade, our TSMART research center at University of Toronto in collaboration with industrial partners has developed advanced medical devices for numerous cutting-edge applications including surgery, stimulation, and sleep apnea. The outcomes of these research works have been published in several prestigious journals along with several US patents.

We are looking for passionate candidates to join our team for our ongoing projects on development of a novel medical device for sleep apnea diagnosis and therapy. The research is performed in collaboration with outstanding researchers in MIE, MSE and IBBME departments. By joining our aerogel team, you will have the opportunity to perform research in one of the sophisticated research labs in Canada, expand your lab skills, and fortify your academic resume by having contribution in academic publications.

In this role, you will be responsible for the following key tasks:

PCB Design: Design and develop printed circuit boards (PCBs) for various electronic components and systems used in our medical device projects.

Arduino Programming: Develop firmware and embedded software for Arduino-based control systems that will be integrated into our medical device prototypes.

Embedded Systems Integration: Integrate the designed PCBs and Arduino-based systems into larger medical device platforms, ensuring seamless communication, control, and operation of the embedded electronics.

Interested candidates should contact Prof. Hani E. Naguib (hani.naguib@utoronto.ca) for more information.

Qualifications and related skills:

- Experienced in PCB design using CAD tools such as Eagle, KiCad, or Altium

- Experienced in programming embedded systems, particularly with Arduino

- Hands-on experience in electronic assembly, prototyping, and troubleshooting

- Familiarity with embedded systems, sensor interfacing, and communication protocols

- Excellent problem-solving and analytical skills

Textile-Based and Wearable Sensors for Healthcare Applications

We are seeking a highly motivated Master of Engineering student to join our research team for an exciting project focused on the development of textile-based and wearable sensors. These sensors will be used for monitoring pressure and temperature distribution in patients with diabetes, who are at risk of developing foot ulcers. This is a unique opportunity to contribute to a meaningful healthcare application and advance your skills in a cutting-edge research environment.

The primary goal of this project is to create innovative textile-based sensors that can accurately measure and monitor the pressure and temperature distribution on the feet of diabetic patients. The sensors will be integrated into wearable devices to provide real-time data, which is crucial for preventing foot ulcers. The successful candidate will be involved in various aspects of the project, including circuit design, data acquisition, data analysis, and the development of smart wearable electronics.

Key Responsibilities

- Design and develop circuits for piezoresistive and capacitive pressure sensors, as well as temperature sensors.

- Acquire and interpret data from these sensors, focusing on the correlation between pressure application and changes in resistance or capacitance.

- Analyze and correlate data to identify patterns and insights relevant to pressure and temperature distribution in diabetic patients.

- Design and prototype smart wearable electronics that integrate the developed sensors.

- Conduct clinical data collection at a hospital premise.

- Perform data-driven materials properties analysis and data processing in materials science.

- Present and document research findings effectively.

- Collaborate with a multidisciplinary team of researchers and clinicians to ensure the practical application of the developed technology.

Required Qualifications & Skills

- Enrolled in a Master of Engineering program, preferably with a focus on electronics, biomedical engineering, or a related field.

- Strong background in circuit design and data acquisition systems.

- Proficiency in data analysis and interpretation, particularly in the context of sensor data.

- Familiarity with piezoresistive and capacitive sensors and their applications.

- Experience or interest in the development of wearable electronics.

- Hands-on experience with wearable sensor design and integration.

- Knowledge of textile-based sensor technologies.

- Strong programming skills for data analysis (e.g., MATLAB, Python).

- Ability to work independently and as part of a collaborative research team.

- Excellent communication and problem-solving skills.

- Experience in data-driven materials properties analysis and data processing in materials science.

- Proficiency in presentation and documentation of research findings.

How to Apply

Interested candidates should submit the following documents:

- A cover letter outlining your interest in the position and relevant experience.

- A current resume or CV.

- Contact information for at least two academic or professional references.

Please send your application materials to Prof. Hani Naguib by naguib@mie.utoronto.ca.

We look forward to receiving your application and exploring the possibility of working together on this innovative project.

Advanced Photovoltaics & Devices Group

Nazir P. Kherani, Professor (ECE / MSE)

E: kherani@ecf.utoronto.ca

Investigation of Rf-Sputtering Parameters for Accurate Metallic and Dielectric Thin Film Growth

Applications of thin films have increased enormously with far-reaching implications for the fields of electronics, optical devices, solar cells and plasmonic sensors – to name a few. In order to fabricate devices at the nano-length scale, care must be taken while engineering various process parameters in relationship to film properties such as thickness and smoothness of metallic and dielectric thin films. Several methods for depositing such films exist. RF sputtering is one of those techniques where both metals and dielectrics can be deposited with great precision. The exact thickness of these films is dictated by various parameters which include: sputtering power, pressure, sputter gas composition, temperature, and film growth duration.

In the context of dielectrics, while radio frequency sputtering overcomes the limitations of the DC diode configuration vis-a-vis sputtering of insulator targets, care must be taken to ensure steady and coherent sputtering rates. The implication of applying radio frequency energy to an electrode is that the difference between atom/ion and electron mobilities is significant. This mobility difference leads to the formation of a negative potential on the target. Unfortunately, this negative bias effect can build up on both electrodes. Precautions can be taken in order to make sure that the target is the electrode that undergoes sputtering [1]. Also, RF sputtering is normally operated at pressures much lower than the DC diode configuration, usually between 0.1 and 3 Pa. The implication of these range of parameters need to be thoroughly understood in order to produce films with well-defined properties.

The objective of this project is to undertake an in-depth study of sputtering parameters.

Interested students will have the opportunity to gain first-hand knowledge of thin film deposition techniques.

In order to successfully complete the proposed project, the collection and interpretation of process data and film properties with respect to the process variables must be achieved. The key milestones include:

- Demonstration of theoretical and relevant experimental knowledge of vacuum systems.

- Fabrication of various metallic (Ag, Ti, Cr) and dielectric (SiNx, AlN, AlN:H) films under various parameters.

- Characterizing thin films using spectroscopic ellipsometry, UV/Vis spectrophotometer, microscopy (SEM, TEM, XRD) to infer thickness, smoothness and morphology of the films, XPS to determine composition.

- Preparation of a final project report describing the theory, experiments, results, analysis, and a detailed concluding outline of the precise relationship between sputtering parameters and properties of thin films.

[1] O’Leary, C. (1999). Design, construction and characterisation of a variable balance magnetron sputtering system (Doctoral dissertation, Dublin City University).

Organic Optoelectronics Research Group

Zheng-Hong Lu, Professor & Canada Research Chair, Organic Optoelectronics

E: zhenghong.lu@utoronto.ca

Metal Electrodes for Electronic Devices: characterization of metal thin-film microstructure, electrical conductivity and optical properties

Relationship between microstructure and electronic structure in organic semiconductors: establishing a relationship between microstructures of organic semiconductors and electronic properties

Perovskite LEDs: development of LEDs based on a new type of perovskite materials

Laboratory for Extreme Mechanics & Additive Manufacturing

Yu Zou, Assistant Professor

E: mse.zou@utoronto.ca

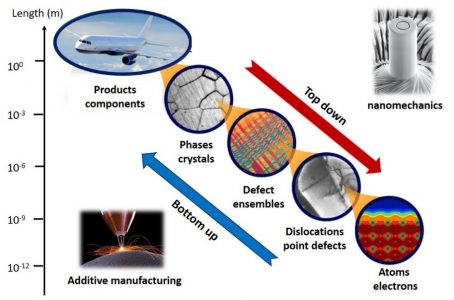

General research activities: Our group uses novel experimental, analytical, and computational tools to explore materials with extreme properties or under extreme conditions, particularly metallic materials. We aim to bridge the gaps between metals, mechanics, and manufacturing (3Ms), covering many length and time scales. Among our research areas of interest are high-entropy alloys, nanomechanics, and additive manufacturing (3D printing). In particular, we want to advance fields of vital importance to society, including the aerospace, biomedical, electronic, environmental, and energy sectors.

M.Eng. projects available: We are currently looking for highly motivated students who enjoy working in a collaborative environment. We welcome students with backgrounds in materials science, mechanical engineering, physics, electrical engineering, and related fields, particularly in physical metallurgy, mechanics, and instrumental design. Current projects are listed below:

- Mechanical and thermal stability of nanostructured high-entropy alloys

- Nanomechanical testing of metallic alloys at small scales and in extreme conditions

- Mechanical properties of titanium and magnesium alloys for aerospace and biomedical applications

- Instrumental design for a laser 3D printing system

- Machine learning for materials design and intelligent manufacturing

If you would like to join us, please contact Prof. Zou (mse.zou@utoronto.ca) for more specific projects and include your CV, a brief statement (a short paragraph) of your interests related to our research, and examples (e.g., project reports or papers) of your recent work.

More available related projects can be found here: https://www.zou-mse-utoronto-ca.net/research

Additive manufacturing and mechanical properties of materials across length scales.

Instrumental design for a hybrid laser 3D printing system

A key hurdle for the mass adoption of Metal Additive Manufacturing (MAM) is the formation of flaws, which leads to inconsistent product quality. To reduce defect density, adaptive control of the parameters during manufacturing is highly desirable. This project aims to design a hybrid vertical milling + directed energy deposition (DED) M-AM system, which will be extended in the future to achieve closed-loop control. A hybrid M-AM system is advantageous in that it makes and postprocesses parts within one integrated process, and that it postprocesses areas that may not be accessible after the prints are finished. The students will be working on building the machine with major components, i.e., laser source, deposition head, powder feeder, CNC vertical mill, etc. The students will collaborate in team with other students to work on the mechanical and electrical integration and make sure all components coordinate properly. Students are expected to have experiences and knowledge in control system design, LabVIEW, PLCs etc.

Hybrid Metal 3D Printer Illustration and Possible Control System Design

Hip Implant with integrated calcium polyphosphate

(Co-supervised by Prof. Marc Grynpas)

There is a need for press-fit hip implants to have a calcium phosphate coating to encourage bone remodeling and bone fixation. The main approach is plasma coating of hydroxyapatite (like the mineral of bone). A technique that is not entirely satisfactory, because of the possible separation of the coating and the implant.

We propose a new method using calcium polyphosphate types of cement to integrate the calcium polyphosphate into the metal of the implants (titanium alloys, stainless steel, and special high-strength alloys). This can be done by ionizing the metal surface in a bath of calcium polyphosphate cement for complete integration of the two materials. This new approach will lead to press-fit implants that will optimize the bone remodeling and the bone fixation of the implants.

Electro-plastic and Plasto-electricity (also photo-plasticity) Effects in Small-scaled Ionic Crystal Systems and Semiconductors

Doped ionic crystals exhibit phenomena called electro-plasticity and plasto-electricity. Interacting with charged vacancies, dislocations can carry charge, interact with an external electric field and thus affect plasticity, or they cause an electric current upon plastic deformation. This research plan focuses on exploring these only poorly studied phenomena at small length scales, i.e. between several microns down to below 100 nanometers.

As the strength levels of ionic crystals are expected to be controllable by electric fields, such materials may be used as switches for micro and nanoelectromechanical systems (MEMS, NEMS). In the opposite mode, detection of a current under plastic deformation, ionic crystals may be used as sensor material for plastic deformation, specifically sensitive to strain gradients.

Autonomous additive manufacturing system (AAMS): a novel in-situ monitoring and closed-loop control process using machine learning

Metal additive manufacturing (M-AM), or metal 3D printing, is a process in which a laser fuses metallic powder to build up parts layer-by-layer directly from 3D digital models. Metal AM will fundamentally change the entire manufacturing industry, from aerospace to biomedical sectors, by 2025 (McKinsey Report, 2019). A key hurdle for the mass adoption of AM is the formation of flaws, such as pores, cracks and other defects, during the manufacturing process, leading to inconsistent product quality. To reduce defect density, it is essential to identify optimal processing parameters (laser power, spot size, scanning speed, and many more) for each material/geometry. However, the sheer size of the parameter space makes it a daunting task. Ideally, adaptive control of the parameters during manufacturing is highly desirable, especially for parts made of multi-materials and with complex geometries.

Integrating novel AM and artificial intelligence (AI) techniques, our team aims to develop the first closed-loop controlled “self-driving laser system” (an analogy to autonomous vehicles) that can sense/predict defects and correct processing parameters adaptively for various materials and part geometries with little human input, significantly improving the quality of AM parts for production and exploiting new avenues for “AM + AI” research towards intelligent manufacturing.

Magnetic field-assisted metal additive manufacturing

Metallic functionally graded materials (FGMs) possess intriguing materials properties, and are well sought-after for various industrial applications. However, conventional manufacturing methods have hindered the design and manufacturing of metallic FGMs. Magnetic field assisted additive manufacturing (MA-AM) uses an external magnetic field to influence the molten metal flow during 3D printing, allowing for locally manipulating the solidified material microstructures, which can consequently lead to graded mechanical properties. Nevertheless, how the magnetic field influences the resultant mechanical properties is not well-understood. In this project, we leverage in-situ high-speed monitoring to collect data on the molten metal dynamics during the MA-AM process. Using a combination of analytical, simulation, and machine learning techniques, the goal is to establish a quantitative relation between the magnetic field parameters and the resultant microstructure and mechanical properties and use it to guide the development of FGMs.

Inverse design of biomedical implant materials via a high-throughput highway

The multidisciplinary and diverse team proposes a high-throughput methodology to accelerate materials discovery and validation by combining materials science, data science, and manufacturing technology. Using machine learning techniques, the team will screen millions of material composition before experimental validation. With the high-throughput mechanical testing method, a huge amount of numbers of samples can be screened and evaluated. Based on this combinatorial method, we aim to achieve material properties that cannot be obtained using conventional techniques. Particularly, the team will focus on the design of novel high-entropy alloys for medical implantation. The proposed transdisciplinary research would considerably reduce materials waste and shorten research and development cycles from discovering new materials to producing final products. Furthermore, new materials with unique properties provide manufacturers with opportunities to produce new products with exceptional functionalities. New generation implant materialswith allows to generate components for best custom fitting, significantly reducing the revision surgery rate for joint replacement.

Design and manufacture of novel wear-and-erosion resistant high-entropy alloys

Equipment used in mineral, oil and gas industries often suffer from severe wear and erosion degradation during operation, such as pumps, valves, cones, impeller, crushers, and ground engagement tools. The wear or erosion induced early failure of these products significantly reduce the service of life of these machines, and, consequently, increase the product and service cost. The academic team at the University of Toronto will collaborate with the Weir Group Plc technical staff to design and fabricate new metallic materials that can significantly improve the wear-and-erosion resistant properties for the components of the mineral, oil and gas products. This project will be focused on an emerging alloy system – high-entropy alloys (HEAs). HEAs are loosely defined as solid-solution alloys that are made of five or more metallic elements in equimolar or near-equimolar ratios, wherein multiple principal elements show a strong tendency of solid-solution hardening effects but also exhibit superior toughness. The search for new HEAs with optimal mechanical properties will be based on a high-throughput combinatorial method. After prescreening of the HEAs at small scales, the U of T team will fabricate large-scale HEAs for testing in real or approximate operation conditions. The new HEAs are expected to exhibit reduced wear and erosion rates compared to typical metallic contact parts

Nanostructured high-entropy alloys as next-generation catalysts for energy applications: from AI-driven accelerated discovery to mass production

Metallic nanoparticles are of interest in a wide range of energy applications, including electrocatalysis, energy storage, and water splitting. Conventionally, such nanoparticles are limited by pure metals, binary or ternary alloys, generally containing noble metals (e.g., Ru, Pt, and Pd). The discovery of new low-cost, high-efficiency catalysts has been highly desirable for decades.

High-entropy alloys (HEAs) – solid-solutions made of five or more metallic elements with equimolar/near-equimolar ratios – exhibit excellent mechanical properties (1-3). Very recently, a few studies have shown that some HEAs also show extraordinary functional properties, especially for catalysis (e.g., ammonia oxidation, hydrogen storage, electrocatalysis, oxygen reduction reaction, and water splitting (4–8)).

Despite this potential, the identification of new and useful HEAs with desired functionalities out of a vast compositional space is a daunting task. The machine learning approach can greatly speed up the discovery of new HEAs for energy applications. Integrated with high-throughput experimentation, the AI and robotics-enabled methodology will provide a new avenue for discovering new HEAs as next-generation catalysts. Towards industrial applications, mass production of HEA nanoparticles is necessary, requiring extreme fabrication conditions, such as ultrahigh heating/quenching rates. Thermal plasmas are capable of rapid heating and cooling of materials (9), thus well suited for large-scale synthesis of HEA nanoparticles.

Data-driven topology and microstructure optimization in metal 3D printing

Metal 3D printing, also known as metal additive manufacturing (AM), offers a unique opportunity for rapid fabrication of metallic components with complex macrostructure (topology) and microstructure (grain/phase size and orientation). Processing conditions (e.g., cooling rate and thermal gradient) influence both macrostructure and microstructure, and eventually, the final properties of products. Scientific challenges in metal 3D printing stem from the diverse processing conditions and their unknown effects on the evolution of various topological and microstructural features, leading to unpredictable performance of components.

Application of the knowledge base of process-structure-property in AM is currently carried out by trial-and-error testing. Because of variations in materials and processing parameters, brute-force approaches hinder rapid qualification and take decades for optimization. In FASE, Prof Steeves is a leader in topology and microstructure optimization using numerical methods; Prof Zou is an emerging expert in metal 3D printing. Leveraging their complementary expertise, the team aims to develop a novel inverse-design methodology for metal AM, by starting with the desired functional properties and identifying optimal topology and microstructures using efficient computational/experimental methods. This project is expected to go beyond conventional paradigms through novel machine learning (ML) algorithms and high-throughput experimentation, building the metal AM process–structure–property knowledge space.

High-entropy alloys for Material Recycling

High-entropy alloys (HEAs) are a promising new materials class that may offer enhanced mechanical, electrical, magnetic, or electrochemical properties over conventional metals and alloys. HEAs are typically defined as alloys made up of 5 or more elements, each in the compositional range of 5-35 at%, that form a single solid-solution phase. Other terms such as medium-entropy alloys (MEAs), complex concentrated alloys (CCAs), and multi-principal element alloys (MPEAs) define various sub-classes of HEAs that may contain less than 5 elements, multiple phases, or non-metallic elements.

While many of the HEAs investigated to date exhibit good mechanical properties in comparison to high-performance materials such as stainless steels and superalloys, the factor that severely limits their potential applications is that of cost. In conventional materials, the base element (e.g. Fe, Al) is often inexpensive in comparison to their alloying elements (Ni, Co, Mo, Cu). However, the near-equimolar range in composition of HEAs would drive the cost of these materials to unacceptable levels.

The recycling industry in one area that we believe could offer some relief to the high cost of HEAs. In many cases, recycling of used materials calls for the separation of all or most of the elements prior to re-use, which itself can be a costly process. As a replacement, we propose to combine recycled metals and alloys of specific composition to form HEAs. In this way we eliminate some costs associated with both recycling as well as HEAs, while also obtaining a mechanically robust material that can be used in high-performance applications.

To begin this study, there are 2 preliminary goals:

- Identify the class(es) of recycled materials for which this would have the highest impact (cost, time, environment).

- Identify the alloys within these classes which could be combined to form either (i) well-studied HEAs, or (ii) new compositions of HEAs.

High-entropy quantum materials

The main research foci will be the accelerated discovery of novel high-entropy quantum materials, such as for unconventional superconductivity and exotic magnetism, by integrating novel machine-learning methods and high-throughput experimentation. A stable form of solid is determined by the ionic radius of constitute elements, preferred coordination and valence state, and so on. In addition to these, at high temperatures, configurational entropy may dominate phase stability. Such entropy-stabilized materials (alloys and oxides) may benefit in many applications. Recently, such entropy-stabilized phases in simple rock-salt oxides with the mixture of several transition-metals exhibit unique electronic properties that are not seen in each constitute oxide (Rost Nature Comm 2015). Our group aims to develop such entropy-stabilized metals/oxides with interesting lattice networks, such as 2D triangular lattice, and explore exotic electronic properties. However, the understanding of how these properties originate from atomic-scale configurations and interactions, which are so important in quantum materials, is still in its infancy. Regarding superconductivity, it is essential to search for new superconductors that exhibit high transition temperature and/or unconventional pairing origin. The research includes the following aspects: (1) novel superconductors at a critical point of competing for electronic orders (pressure up to 10 GPa); (2) searching superconductivity under the influence of strong spin-orbit coupling, especially for 4d and 5d transition-metal elements.

Computational Materials Engineering Laboratory

Chandra Veer Singh, Associate Professor & Associate Chair, Research

For more info, contact: chandraveer.singh@utoronto.ca

Web: http://www.ecf.utoronto.ca/~singhc17/

AI enabled design of high entropy alloys for structural applications

Design of new alloys has been traditionally achieved through trial-and-error, which tends to be time consuming and overly expensive. In this project, we will aim to design new high entropy alloys using a combination of high throughput simulations, machine learning, and available experimental data. Newly proposed alloys will be analyzed using quantum-mechanical simulations to evaluate their mechanical properties for potential structural applications. This project will be conducted in collaboration with National Research Council of Canada (NRC) via their new AI for materials initiative. The students will be trained on atomistic simulations, and the development of ML algorithms; hence, consequently, the students will gain excellent exposure to the emerging field of data sciences in MSE. The complete project work can be achieved remotely, on supercomputing facilities provided via Compute Canada.

AI guided design of photocatalysts for CO2 and nitrogen reduction reactions

Since the discovery of graphene, there has been intense research in developing two dimensional materials for various applications in electronics, energy, healthcare and transportation industries. Consequently, more than 20 such materials have been synthesized, with intriguing electronic, chemical and mechanical properties. Many more have been theoretically proposed. In this project, the student will utilize atomistic simulations to study CO2 and nitrogen reduction on a broad range of 2D materials substrates and metallic single atom, double atom, and triple-atom catalysts. ML algorithms will then be used to generate correlations between catalyst chemistry and predicted ability for CO2 and nitrogen reduction. The students will be trained on atomistic simulations, and the development of ML algorithms; hence, consequently, the students will gain excellent exposure to the emerging field of data sciences in MSE. The complete project work can be achieved remotely, on supercomputing facilities provided via Compute Canada.

Discovery, design, and optimization of all solid-state battery materials using machine learning

Battery research is at the forefront of electric vehicles of the future. However, the current Li-ion battery technologies utilize liquid electrolytes, which are prone to cause fire hazards. Therefore, solid state electrolytes (SSEs) are being developed for future battery technologies. Nevertheless, the current SSEs have low ionic conductivities, which lead to a very slow charge/discharge rate, and lower battery capacities. In this project, the students will work on developing a comprehensive database for various properties of potential chemical compounds and utilizing the latest machine learning algorithms developed in our lab to propose new SSE chemistries. The best potential compounds will be further investigated using density functional theory (DFT) simulations. This project is in collaboration with National Research Council of Canada (NRC) via their collaboration center with UofT on green energy materials (CCGEM) – in the medium-term, our collaborators at NRC would conduct experimental testing on proposed materials. The students will be trained on atomistic simulations, and the development of ML algorithms; hence, consequently, the students will gain excellent exposure to the emerging field of data sciences in MSE. The complete project work can be achieved remotely, on supercomputing facilities provided via Compute Canada.

Finite element based multiscale analysis of progressive failure in composites and additively manufactured parts

Due to their lightweight, composites are widely used to manufacture wind turbine blades. However, accurately predicting progressive failure in composite materials under multiaxial and fatigue conditions has been a difficult task. Similarly, predicting failure in 3D-printed parts is quite complex. In this project, the student will work on improving a multiscale methodology to investigate failure in additively-manufactures parts and composite materials, implement the developed algorithm in commercial finite element codes, and apply for practical structures. The module developed from the project will be highly valuable in design of safe and long-serving airplane parts and renewable energy structure such as wind turbines. The students will be trained on multiscale failure modeling, and the development of python codes for FE applications; hence, consequently, the students will gain excellent exposure to the computational mechanics field. The complete project work can be achieved remotely, on supercomputing facilities provided via Compute Canada, and in-house high-end workstations.

Sustainable Materials Processing Research Group

Mansoor Barati, Professor, Gerald R. Heffernan Chair in Materials Processing & Associate Chair, Undergraduate Studies

E: mansoor.barati@utoronto.ca

Developing a Sustainability Index for Consumer Products

Numerous surveys are showing that consumers are preferring sustainable products when given a choice, and are ready to pay a higher price for them. However, the onus is often left on the consumers to do researches of different extent, rely on unquantified statements of the producers, or trust the word-of-mouth to make a choice. It is believed that a simple-to-read index (or small number of indices) will allow consumers to make data-supported informed choices about purchasing sustainably produced goods. The purpose of this study is to conduct a survey of the sustainability indicators for consumer products, and synthesize the information to produce a quantitative metric that could potentially be applied to the product labels.

SO2-Free Extraction of Nickel from Sulfide Ores: Alternative Iron Sources

Nickel is an essential strategic metal with many applications in our daily life with applications in stainless-steel products, batteries, etc. , stainless steel pipe, batteries etc. Annually almost half of the total nickel is produced from sulfidic nickel ores with a considerable amount of sulfur dioxide emissions. Therefore, it is of significant interest to mitigate the potential SO2 emissions when extracting nickel from the sulfidic ores. We are working on a novel method of Ni extraction that eliminates smelting-oxidation of the Ni concentrate, thus recovering Ni into a metal while leaving sulfur in a solid residue (hence no SO2 emission). As part of this study we would like to look into the use of an inexpensive source of one of the additives in the process (iron), for example by using iron oxide and reductant. The student will conduct an experimental study on this aspect of the work and will me mentored by senior graduate students and the PI.

SO2-Free Extraction of Nickel from Sulfide Ores: Optimization of Iron Addition

Nickel is an essential strategic metal with many applications in our daily life with applications in stainless-steel products, batteries, etc. , stainless steel pipe, batteries etc. Annually almost half of the total nickel is produced from sulfidic nickel ores with a considerable amount of sulfur dioxide emissions. Therefore, it is of significant interest to mitigate the potential SO2 emissions when extracting nickel from the sulfidic ores. We are working on a novel method of Ni extraction that eliminates smelting-oxidation of the Ni concentrate, thus recovering Ni into a metal while leaving sulfur in a solid residue (hence no SO2 emission). As part of this study we would like to look into the effect of iron addition to the concentrate (as one of the variables) aiming to reduce the use of iron and improve the product grade. The student will conduct an experimental study on this aspect of the work and will me mentored by senior graduate students and the PI.

Electronic-Photonic Materials Group

Harry E. Ruda, Professor, Stan Meek Chair Professor in Nanotechnology

E: harry.ruda@utoronto.ca

CO2 sequestration with nanoparticle-sand beds

With increasing urgency in addressing climate change, solutions are required to mitigate and eliminate emissions into the atmosphere, particularly greenhouse gases (GHG). The most significant GHG (in terms of volume produced) is CO2. To avoid adding more CO2 to the atmosphere as a result of their industrial operations, our industrial partner has identified sub-terranean sequestration of CO2 as a possible means to accomplish this. Part of this solution involves the development of suitable adsorptive beds in which the CO2 can be stored. A number of factors are available for designing engineered adsoprtive beds, but fundamentally increasing available adsorptive surface area is key. One way to achieve this is through the use of nanoparticles interspersed within the adsorptive bed to create a multi-scale, multi-composition matrix. This project will look at the role of nanoparticle material, size, and concentration on CO2 adsorption selectivity, through empirical or numerical methods.

Nanoimprinting lithography (NIL) of sub-micron structures

In developing sub-micron/nanoscale structures, relatively expensive and/or time-consuming process steps involving tools such as e-beam lithography (EBL) and reactive ion etching (RIE) are employed. While this can provide for high resolution structures, this is not a feasible fabrication method for massive scale-up of production, especially if the structures are to be used once, e.g., to avoid cross-contamination after exposure to a sample in sensing applications. The structures generated from EBL/RIE can be used as master templates from which casts can be made using cheaper/simpler processes, such as UV epoxy curing, or PDMS casting. This project will look to develop reliable process steps to replicate structures (designed for sensing applications) with sub-micron/nano-scale features, to characterise the resulting replicates through a variety of techniques.

Application of nanostructures to radiation monitoring in cancer treatment

FLASH radiotherapy is a newly developed radiotherapy method using ultra-high dose rate (UHDR) treatment. However, it has not been put to clinical use due to the lack of a corresponding dosimeter and dosimetric system that can work reliably under UHDR. A potential route to developing an appropriate dosimeter is through optically stimulated luminescence using nanostructures to detect the ionizing radiation. Our previous work with ZnSe and BeZnO nanostructures have shown that, through control of composition, geometry, and dimensions, spectrally tunable structures may be generated, with picosecond response and very hugh photoconductive gain. Such structures make ideal candidates as dosimeters based on OSL. In this project, the fabrication of suitable nanostructures with control of composition, geometry, and dimensions will be explored, as will their subsequent characterisation and optical response to exposure to radiation. This project involves collaboration with Princess Margaret Hospital.

Reliability studies of photovoltaic modules by Finite Element Analysis FEA

Due to heat generation during operation and conditions of specific geographic locations of photovoltaic (PV) module installations, temperature variation and harsh environmental effects critically affect their reliability. The project involves use of FEA modelling of thermomechanical behaviour of PV modules and correlating the results with test data from the industry. In particular, finger breakage and mechanical failure are observed more frequently at the ends of a cell busbar. 3D FEA modelling will be used to predict the displacement and stress concentration around these regions, and help guide towards more reliable designs with better thermal management.

High throughput imaging-based analysis of plant growth

Next generation crop treatments, such as molecular delivery-based Smart Crop Technology (SCT), are being designed to be highly specific to asingle species or even subspecies of organism to ensure Canadian Farmers have the tools they need to remain economically viable and produce high quality food for Canadians and the international community. There are two components to SCT – the nano-carrier that can penetrate into the tissues of the target organism, and the programmable effector molecule complexed to the carrier that acts to modify the biochemistry. A key part to studying the performance of SCT is through its monitoring through non-invasive, high-throughput imaging-based phenotyping techniques. This project involves developing automated phenotyping to get contextual data about nano-material (NM) penetration and toxic impacts of NM treatments, with plant height, stem width, and leaf surface area the phenotypes that we aim to extract. Logging the physical attributes of the plants will be valuable in monitoring and controlling this variable.

Development of nanowire field-effect transistors for biochemical sensing

Development of state-of-the-art biochemical sensors is an ever-evolving field where nanotechnology is increasingly useful. A sensor with the ability to distinguish multiple species can serve as a protection to the end-user when exposed to dangerous gases or hold use in biological cases where one wishes to identify specific molecules with pristine accuracy. Indium Arsenide (InAs) based nanowire field-effect transistors (NWFET) are used due to their high sensitivity to surface binding events. Creation of these sensors requires designing/improving upon robust processing techniques using modern fabrication methods. Our previous experimental work with these sensors has established that InAs NWFETs are capable of sensing ultra-low analyte concentrations (<50 ppb). Creation of a library of molecular sensing responses and the underlying binding mechanism will hold significance as the NWFET sensors technology matures. Furthermore, engineering a miniaturized sensing platform that is low-cost, efficient, and diverse in its sensing ability will have widespread utility and value.

Functional and Adaptive Surfaces

Benjamin D. Hatton, Associate Professor & Associate Chair, Graduate Studies

E: benjamin.hatton@utoronto.ca

Rates of drug release from thin films

Our group has developed antimicrobial drug-loaded films, in collaboration with Dentistry, to release these drugs in dental or orthopedic implant applications. This project aims to measure the rates of drug release over time, using precise measurements of density changes in the films. One technique will be to use ellipsometry (Hatton group), which is a powerful method to measure the refractive index of thin films. In addition to ellipsometry, you will be involved in making the drug-loaded films, and use scanning electron microscopy (SEM), x-ray diffraction (XRD), and potentially x-ray photoelectron spectroscopy (XPS) and TEM.

Drug-silica nanocomposite particles by spray formation

Recently our group has published papers on the self-assembly of certain (commercially available) drugs with silica (glass) to form interesting nanocomposite structures (C. Stewart, Y. Finer, B.D. Hatton, Drug self-assembly for synthesis of highly-loaded antimicrobial drug-silica particles, Scientific Reports 8 (2018) 895.). This project aims to further develop a spray method to form these drug-silica particles rapidly and uniformly, based on preliminary results. Characterization will include optical microscopy, scanning electron microscopy (SEM), and x-ray diffraction (XRD).

Writing nanoporous carbon structures on a surface using a programmable XY ‘pen’

This project aims to program an XY translation stage for the writing onto surfaces of colloidal particles (silica glass, ceramic or polymer) as an ‘ink’ suspension that can self-assemble into self-organized nanocomposite structures. Previously we have developed methods to directly assemble particles into highly-ordered, close-packed (FCC) structures through ‘co-assembly’ (Hatton et al, “Assembly of large-area, highly ordered, crack-free inverse opal films” PNAS 2010). Polymeric spheres can act as a template for a matrix material, such as silica glass, carbon nanotubes or graphene. Now, we would like to write these carbon structures on a surface using a programmable stage, to deposit complex layered structures.

Self-cleaning of superhydrophobic plants

There are many examples of non-wetting, superhydrophobic plants (and insects), based on the Cassie-Baxter ‘lotus’ effect. This lotus effect is known to help such surfaces ‘self clean’ through the rolling action of water droplets to pick up dust/dirt particles, and is a good example of ‘bio-inspired’ design. But there have not been detailed studies of this self-cleaning mechanism. This project aims to collect a wide range of plant specimens (from natural environments, researchers, botanical collections) and experimentally test their self-cleaning properties. Also may include testing microbial adhesion. Characterization will include contact angles, optical microscopy and scanning electron microscopy (SEM).

Laboratory for Nanobiophotonics

Kai Huang, Assistant Professor

E: nanokai.huang@utoronto.ca

Controlling the Nanocrystal Growth of Persistent Luminescence Nanoparticles

Persistent luminescence nanoparticles (PLNPs) exhibit a distinct property of emitting light continuously after the excitation light ceased, by storing the excitation energy in traps for subsequent slow release. Benefiting from the exemption of real-time excitation, PLNPs have immense potential for various biomedical applications, such as background-free bioimaging, deep-tissue photodynamic therapy, and long-term biomolecule tracking. However, conventional solid-state syntheses or hydrothermal syntheses have limited control of the nanocrystal growth process due to the limited tunability of the reaction conditions. In this project, we aim to apply microwave synthesis, which provides real-time fine-tuning of the reaction conditions, to achieve controllable nanocrystal growth of PLNPs. Objectives of this project include: (i) to control the PLNPs nanocrystal growth by tuning the heating-up, incubation, and cooling-down stages during microwave synthesis; (ii) to characterize the crystal structure, morphology, and particle size distribution of the PLNPs; and (iii) to investigate the size/morphology-dependent persistent luminescence of PLNPs.

Development of Mechanoluminescence Nanomaterials with Enhanced Luminescence for Stress Sensing

Mechanoluminescence (ML) nanomaterials are materials that emit light under mechanical stress or pressure. Due to their unique properties, they have attracted significant research interest for potential applications in sensing, imaging, and structural health monitoring. ML nanomaterials have high surface area and small size, allowing for high-resolution sensing of small changes in pressure or stress. However, conventional ML nanomaterials suffer from weak luminescence and non-tuneable emission spectrum. In this project, we aim to enhance the luminescence of multi-color ML nanomaterials by optimizing the nanomaterials preparation conditions, making them advantageous for stress sensing. Objectives of this project include: (i) to synthesize multicolor ML nanomaterials through high-temperature solid reactions; (ii) to characterize the crystal structure, morphology, and particle size distribution of the synthesized materials; and (iii) to apply the ML nanomaterials for stress sensing.