Unveiling the Plastic Deformation and Phase Transformation of Quasicrystal

Quasicrystals – materials in which the atoms show long-range order but have no finite, periodically repeated unit cell – have fascinated materials scientists, while their practical use has been limited by their brittleness below about 3/4 of their melting temperatures (~500 °C). How quasicrystals are plastically deformed below 500 °C is still poorly understood.

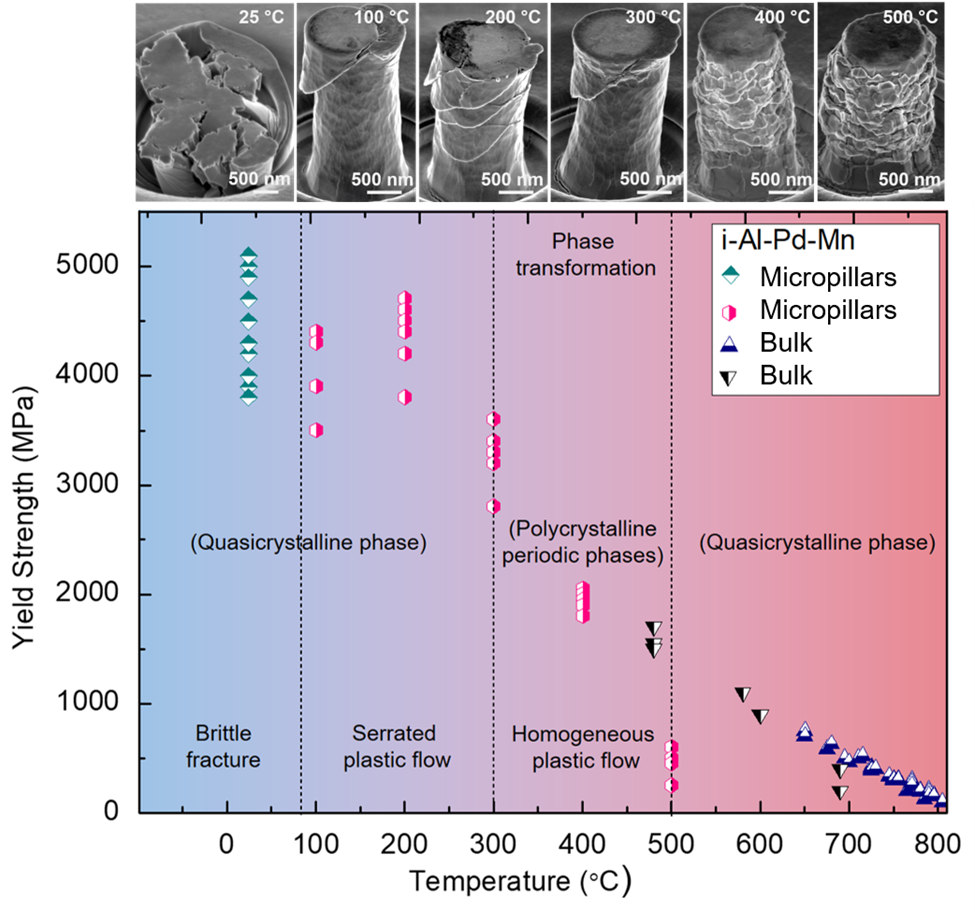

An international team of researchers, led by Prof. Yu Zou (UofT) and Dr. Jeffrey M. Wheeler (ETH Zurich), performed micro-thermomechanical testing on an Al-Pd-Mn quasicrystal to unveil its deformation mechanisms over an unexplored temperature range from room temperature to 500 °C. They observed fascinating phenomena, including sample size reduction, serrated plastic flow, phase transformations, and grain refinement.

Another interesting phenomenon reported in their publication is about phase transformation of quasicrystals. The Al-Pd-Mn quasicrystal is thermodynamically stable at high temperatures (above 500 °C) and kinetically stable at relatively low temperatures (below 300 °C). The team found the single quasicrystalline structure transformed into polycrystalline regular crystals (AlPd, Al3Pd2, and Al8Mn5) between 300 and 500 °C.

This study bridges the gap between room-temperature and high-temperature plasticity in quasicrystals, demonstrating an opportunity to study the deformation of complex materials in broad size and temperature regimes.

SEM micrographs (upper) of i-Al-Pd-Mn micropillars after compression in the temperature range 25-500 °C. Yield strength as a function of temperature for the micropillars (lower), exhibiting three regimes of mechanical behaviors with the occurrence of phase transformation from quasicrystalline phase to polycrystalline periodic phases.

Nanomechanical Characterization of Additive Manufactured Titanium Alloys

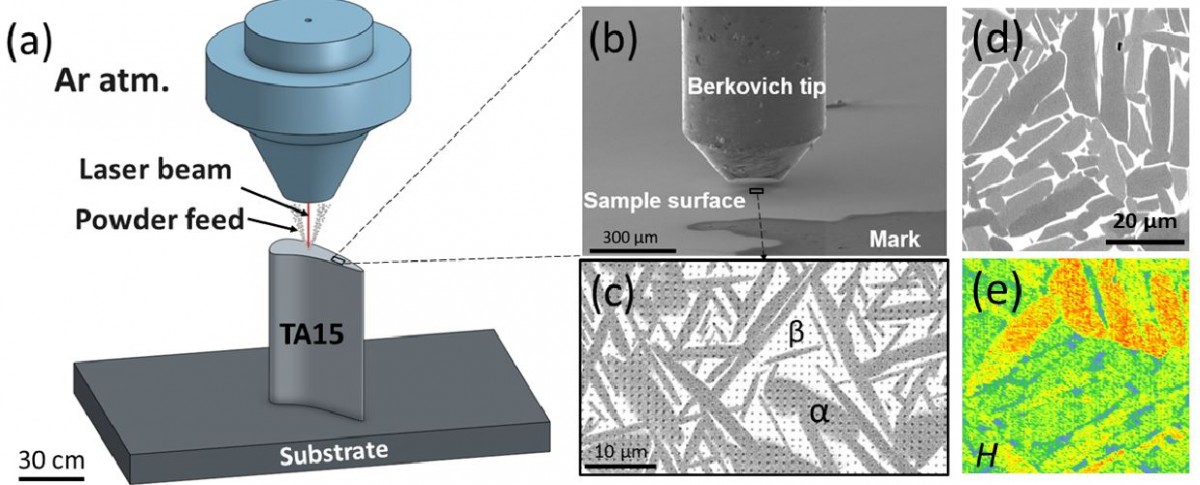

Additive manufacturing (AM) techniques provide new opportunities for manufacturing industries, from the production of aerospace engines to hip implants. Additive manufactured parts, however, possess complex microstructure with refined grains or phases. The mechanical properties of each phase or grain and its contribution to the overall mechanical properties of bulk components are still unknown.

Prof. Yu Zou and his research group employed high-speed nanoindentation mapping to characterize the local mechanical properties of individual phase/grains of additive manufactured dual-phase titanium alloy (Ti-6Al-2Zr-1Mo-1V) and γ-TiAl/Ti2AlNb gradient alloys. For the titanium alloy, they quantitatively characterized nanohardness (H) and elastic modulus (E) of each phase in the material and investigated the mechanical response to thermal treatment (see article). For the γ-TiAl/Ti2AlNb graded material, they statistically studied the microstructure-property relationship in the transition zone between γ-TiAl and Ti2AlNb. There findings indicate existing correlations between the mechanical properties (H and E) and microstructure/ phases at the sub-micrometer length scale in the transition zone (see article).

Zou’s group have also published a review article titled “Additive manufacturing of titanium alloys for aerospace applications: directed energy deposition and beyond Ti-6Al-4V” (see article).

(a) schematic image of the laser melting deposition (LMD) system for additive manufacturing of the titanium alloy (TA15), (b) SEM image of the nanoindenter with the Berkovich tip on the titanium sample surface, (c) The BSE image revealing the nanoindentation impressions on the α and β phases of the TA15 sample after the high-speed nanoindentation mapping, (d) and (e) show the BSE image and the corresponding H distribution,

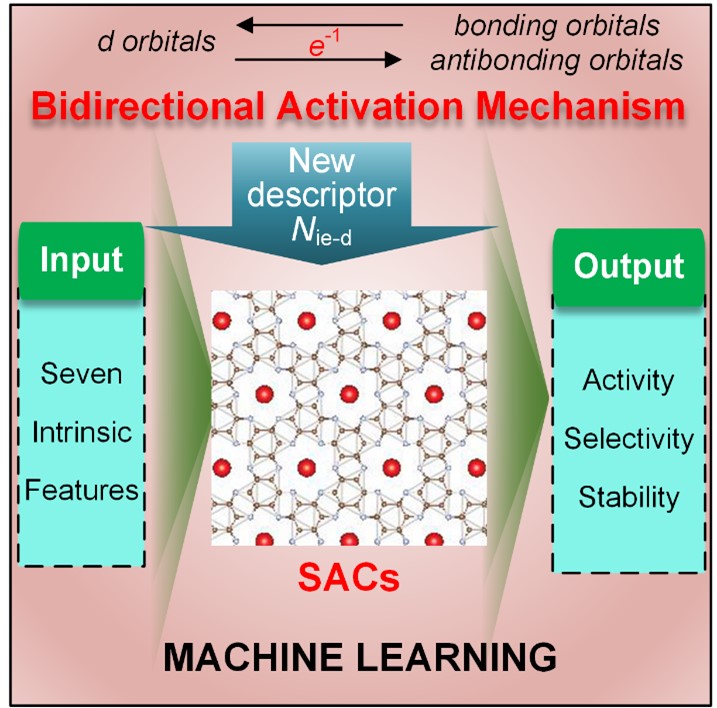

Machine Learning Accelerated Discovery of Single Atom Catalysts Based on Bidirectional Activation Mechanism

Dr. Zhi Wen Chen (Postdoctoral Fellow) and Prof. Chandra Singh work on the design and development of single atom catalysts (SACs) through density functional theory (DFT) and machine learning (ML). SACs have provided new impetus to the field of catalysis. The key challenges in the development of SACs are to explore the structure-activity relationship and predict the catalytic performance of SACs. They address the challenges by examining a series of SACs supported on 2D materials. First, they propose a bidirectional activation mechanism for nitrogen reduction reaction (NRR), which not only explains some experimental results, but also could be extended to other catalytic reactions, laying the foundations for constructing catalytic theory. Moreover, their developed ML model could predict the catalytic activity of SACs for NRR with reliable accuracy, validated by previous DFT and experimental works. Their results provide new insights in catalysis theory and will accelerate the discovery of SACs, showing a huge influence for real-world energy field. Click here to view their publication.

Zhi Wen Chen (left) and a bidirectional activation mechanism with a new descriptor of Nie-d is proposed for providing new insights in catalysis based on DFT calculations. Their developed ML model with high accuracy could accelerate the design of SACs for NRR (right)

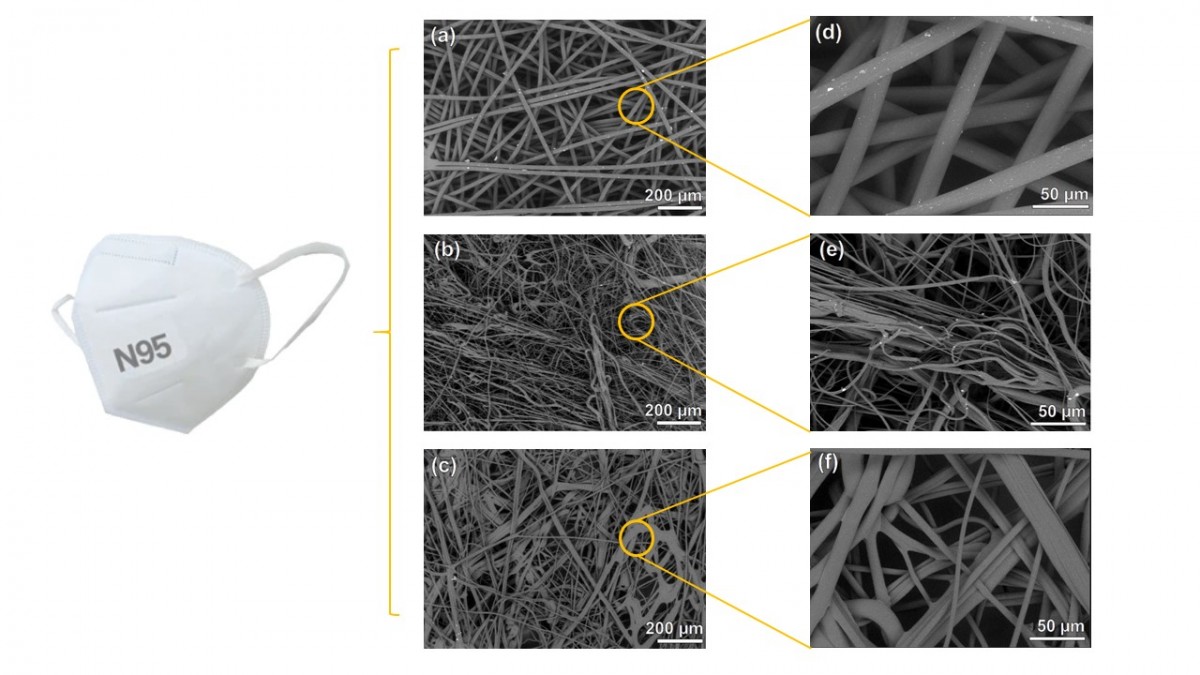

Structural Characterization of Commonly Available Respirators and Facemasks

Masks and respirators are arguably the most important piece of PPE in current times. Different kinds of facemasks and respirators offer varying degree of protection to users. Researchers from Materials Science and Engineering (Dr. Jason Tam, Prof. Jane Howe, and Prof. Doug Perovic), Chemical Engineering (Medhavi Patel) and Bell University Labs Chair in Human-Computer Interaction (Prof. Matt Ratto) and Department of Mechanical & Industrial Engineering (Hao Shi and Prof. Hani Naguib) are working on determining the structural characterization of commercially available respirators and facemasks in terms of the morphology, materials used in design, and the moisture retention capabilities of the various layers of the respirators and masks.

This research is conducted using Hitachi SU5000 SEM located in the Ontario Centre for the Characterization of Advanced Materials (OCAAM) laboratories at the University of Toronto. SEM study performed at the Ontario Centre for Characterization of Advanced Materials (OCCAM) in the University of Toronto is funded by Canadian Foundation for Innovation. The authors would also like to gratefully acknowledge Mitacs for supporting their research.

Scanning electron microscopy (SEM-EDS) is used to characterize the morphology of the various layers of the masks. Fourier transform infrared spectroscopy (FTIR) analysis is used to characterize the material and conduct the moisture retention analysis.

The structure of the outer, filtration and inner layer of a N95 respirator: (a) outer, (b) filtration and (c) inner layer at lower magnification. (d) outer, (e) filtration and (f) inner layer at lower magnification at higher magnification for N95 mask

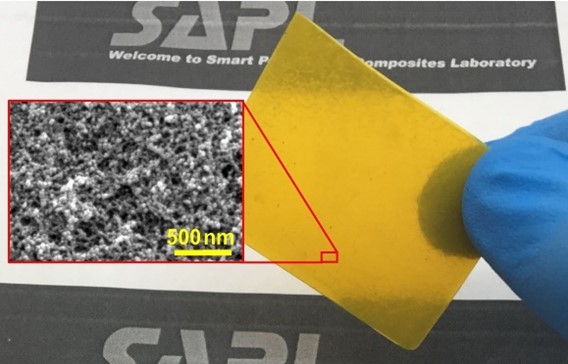

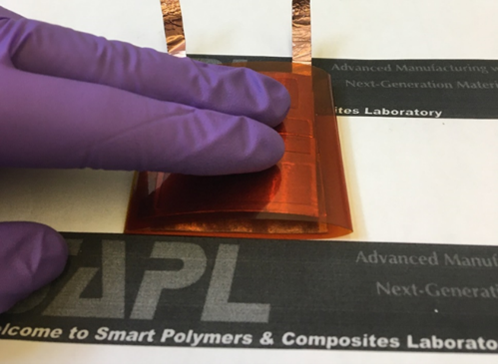

High-Performance Triboelectric Nanogenerators for Mechanical Energy Harvesting and Self-Powered Sensing

Zia Saadatnia (Postdoctoral Fellow- MIE) and Prof. Hani Naguib worked on the design and development of high-performance Triboelectric Nanogenerators (TENG) for energy harvesting and self-powered sensing applications. The TENG is a novel technology for the Mechanical-to-Electrical energy conversion based on the contact electrification of two dissimilar materials, and electrostatic induction. First, they proposed a novel method to enhance the performance of TENG systems through improving the surface morphologies of the applied materials. The proposed method is based on the hot embossing of thin-film polymers on colloidal self-assembled micro-particles. Then, they worked on developing a unique type of nano-porous materials namely organic aerogel. Specifically, they worked on the fabrication of Polyimide and Polyurethane aerogels to demonstrate how they are useful in the TENG systems. They proved that the proposed aerogel materials could remarkably enhance the performance of the TENG through tailoring their dielectric properties, porous structures, and surface morphologies.

Zia Saadatnia (left) a polyimide aerogel with a nano-porous structure (The SEM image shown in the inset of the figure) which can enhance the output performance of TENG systems significantly (middle), a fabricated flexible TENG system in SAPL using the surface modified thin-film polymers which can harvest the mechanical energy through pressing and releasing for powering microelectronics (right)

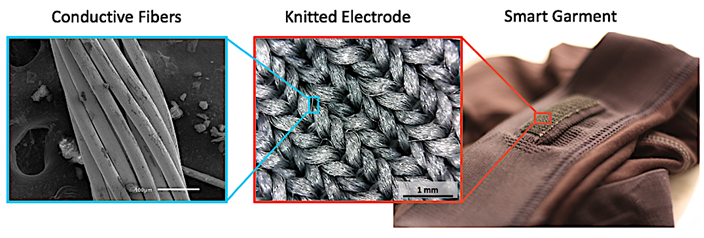

Development of Multi-functional Electroactive Fibers for Electrophysiology Applications

PhD candidate Ladan Eskandarian working with Professor Hani Naguib focuses on developing new multifunctional fibers and yarns to develop textile electrodes for electrophysiological application. Smart textiles can be presented as part of everyday clothing that are ubiquitous and minimize the need for habit changes. Therefore, smart garments with embedded textile electrodes can introduce a new medium for continuous monitoring of physiological markers such as electrocardiography (ECG), electromyography (EMG), and electroencephalography (EEG). Additionally, smart garments are suitable for manufacturing, scaling and equitable distribution, as they can be readily produced by combining conductive and nonconductive materials via conventional textile production processes, such as knitting, weaving, or embroidery. This work has been supported by the Natural Science and Engineering Research Council of Canada NSERC and Mitacs grants in collaboration with Myant Inc for Textile Computing.

Ladan Eskandarian, PhD Candidate (left) a conductive multifilament yarn directly knitted into a textile electrode which is embedded into a smart garment (right)

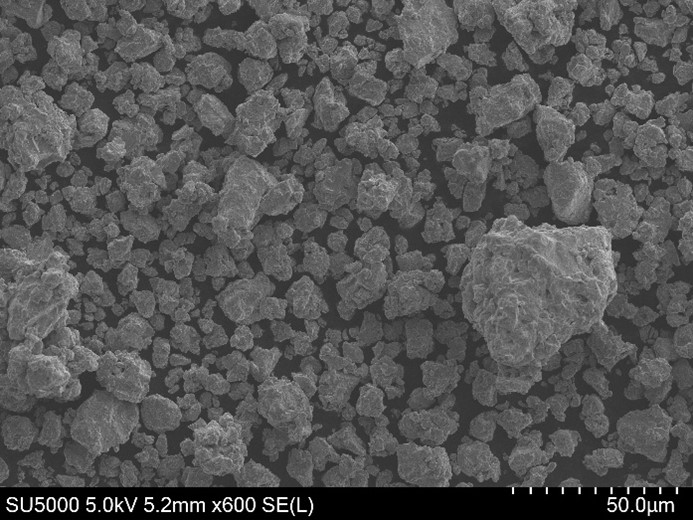

Synthesizing Low-cost, Nanopowders that can be Readily Commercialized as Electrocatalysts

Professor Steven Thorpe and the Surface Engineering and Electrochemistry (SEE) group is finding ways to synthesize low cost, nanopowders that can be readily commercialized as electrocatalysts in both water electrolysers and fuel cells.

The development of both novel chemistries and processing methodologies will enable significant cost reductions with improved performance in electrochemical devices. This work has been supported in part by a combination of NSERC Discovery Frontiers Grant, NSERC CRD grants, and NSERC Discovery grants in collaboration with a number of industrial partners.

Professor Steven Thorpe (left) and a Ni-base hydrogen evolution catalyst powder (right) for use in future AEM water electrolysers

The First Metal Additive Manufacturing Laboratory in the University of Toronto

Professor Yu Zou group focuses on 3D printing of metals for structural applications, such as in aerospace, automobile, tooling, nuclear and biomedical sectors. His Metal Additive Manufacturing Laboratory includes a metal 3D printer which is a laser power bed fusion system that allows creating complex structures using both conventional and new materials, providing great flexibility in the design space (see the image below). Combining with alloy design (e.g. high-entropy alloys), machine learning (in-situ monitoring), and multiscale mechanical testing, his group aims to develop next-generation structural materials and components for serving in extreme harsh conditions.

The equipment is funded by the Canada Foundation for Innovation (CFI) and the Ontario Research Fund (ORF). The related search projects are supported by the Natural Sciences and Engineering Research Council of Canada (NSERC), New Frontiers in Research Fund (NFRF) and the Dean’s Spark Professorship U of T Engineering.

Additive manufacturing, sometimes known as 3D printing, will fundamentally change the entire manufacturing enterprise, contributing more than ten billion dollars to Canada’s annual GDP and creating over 100,000 jobs by 2025. In contrast to the popular polymer 3D printing, metal 3D printing is an expensive and very complicated process, representing the highest level of synergy of many disciplines.

Associate Professor Yu Zou (left) and 3D-printed UofT and MSE logos using brass (right)

Making an Impact with Next-generation Materials

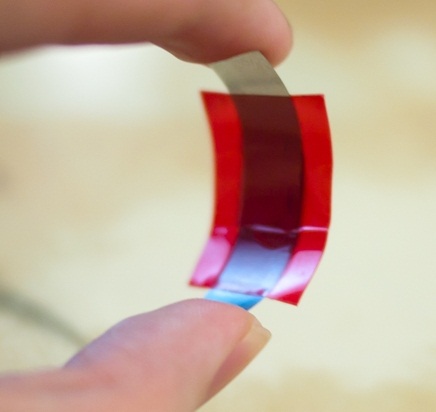

Professor Keryn Lian is finding ways to boost the amount and density of energy stored in thin, solid electrochemical capacitors.

The thin cells, combined with batteries or solar cells, form new hybrid energy devices that help prolong fast and safe energy delivery. She is one of eight researchers across U of T Engineering working on the Collaborative Research and Training Experience (CREATE) program in Distributed Generation for Remote Communities (DGRC), funded by the Natural Sciences and Engineering Research Council of Canada.

Led by Professor Cristina Amon, Dean of the Faculty of Applied Science & Engineering, the project will bring clean energy alternative technologies to remote communities in Canada.

Associate Professor Keryn K. Lian (left) and a solid polymer-based, thin-film super-capacitor made in her Flexible Energy & Electronics Lab (right)

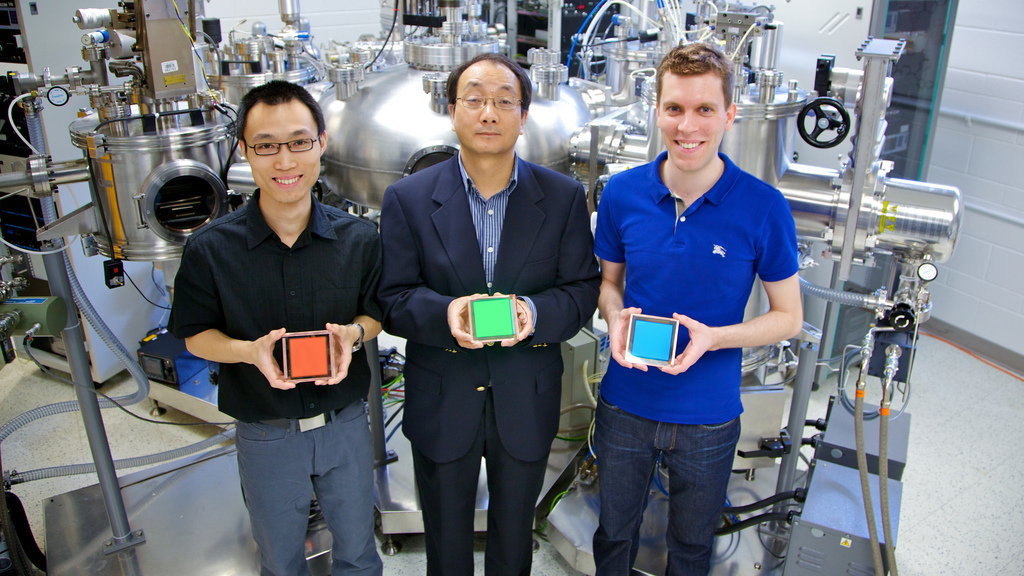

The Future of OLED Technology

Chlorine has played a pivotal role in helping a research team develop the most efficient, cost-effective and environmentally friendly light-emitting diodes yet made.

By adding a one-atom thick layer of chlorine to ITO, the team was able to create record-breaking OLED efficiency

Doctoral researchers Michael Helander and Zhibin Wang discovered that chlorine can drastically change the properties of indium tin oxide (ITO)—the material used in flat-panel displays.

By adding a one-atom thick layer of chlorine to ITO, the team, led by Professor Zheng-Hong Lu, Canada Research Chair in Organic Optoelectronics, was able to create record-breaking organic light-emitting diodes (OLEDs) using one or two organic layers instead of the four or five layers typically required. With fewer layers, the chlorine-OLEDs (Cl-OLEDs) will not only be less complex, but easier to manufacture.

Cl-OLEDs also make it possible to create displays on thinner, pliable surfaces instead of traditional glass plates.

“For years, the biggest excitement behind OLED technologies has been the potential to effectively produce them on flexible plastic,” says Lu. Now there is potential to create paper-thin light displays that could be folded and stuffed into a wallet or used in large areas for ultra energy-efficient indoor lighting.

Doctoral researcher Zhibin Wang, Professor Zheng-Hong Lu, and doctoral researcher Michael Helander present their revolutionary Cl-OLED technology.