The 2008 Sunrise Propane plant explosion in Toronto is one of the case studies taught in Professor Doug Perovic’s Forensic Engineering course. The course will be part of a new Certificate in Forensic Engineering, launching in Fall 2017. (Credit: Michael Gill via Flickr, under creative commons)

December 13, 2016 | By Krista Haldenby

When the Sunrise Propane plant exploded in August 2008, killing plant worker Parminder Saini, police, fire and ambulance were called first — and then forensic engineers.

Forensic engineers are trained to find and analyse data from disasters, accidents and failures, and present an unbiased assessment of what the underlying cause may have been.

“Unlike some witnesses, physical evidence has no opinion, no bias and never lies,” says forensic engineer and MSE Professor Doug Perovic.

Forensic engineer Professor Doug Perovic dismantled propane tanks involved in the Sunrise Propane plant explosion to look for the cause of the accident. (Courtesy: Doug Perovic)

The Sunrise Propane explosion, Radiohead stage collapse in 2012, falling glass from the Shangri-La hotel in Toronto, and the painful fracture of an Ottawa woman’s prosthetic hip implant are just four of the cases taught in Perovic’s Forensic Engineering course, the first of its kind in Canada and now core to a new Certificate in Forensic Engineering offered by the University of Toronto’s Faculty of Applied Science & Engineering. The certificate will be offered to undergraduate students starting in 2017-2018.

Perovic is one of the top experts in his field, having led more than 500 product liability investigations over a 25-year career. In his course, students are exposed to investigative techniques such as how to conduct destructive and non-destructive testing, how to interpret the evidence left behind on a fracture surface or at the scene of a vehicle collision, and how to narrow down the origin and cause of a fire.

The course features renowned guest experts from Canada’s top forensic engineering firms to cover principles of investigation involving product failure, automobile and aircraft accident reconstruction, and fire and explosion. It concludes in a mock trail, with lawyers from top law firms participating in demonstrations of expert witness cross-examinations.

“Most importantly, this course teaches students how to apply their engineering knowledge to ask the right questions when investigating a complex, often messy, real-world problem from beginning to end,” says Perovic.

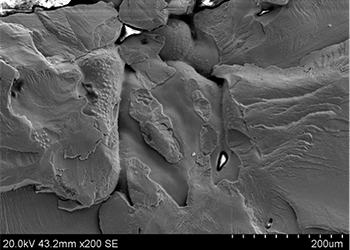

This image, generated by a scanning electron microscope, reveals the fatigue crack origin in a hip implant caused by a manufacturing defect. (Courtesy: Doug Perovic)

Students will examine physical evidence using sophisticated lab equipment at the Ontario Centre for the Characterisation of Advanced Materials (OCCAM), jointly operated by the Materials Science & Engineering and Chemical Engineering & Applied Chemistry departments. OCCAM’s scanning electron microscopes are a powerful tool for forensic engineers — they can produce high-resolution images of a fracture surface, which can help identify the fracture origin and indicate the mode and mechanism of failure.

Components from surgical implant failures, athletic equipment failures, corrosion investigations and foreign materials and residue analysis are a few examples of the evidence that has been brought to OCCAM for investigation. OCCAM’s second arm, which evolved from Surface Interface Ontario and specializes in surface analysis, is also accustomed to the investigative scene. The facility, located at the west end of the Wallberg Memorial Building, completes a quarter of its analysis work for forensic investigations and failure analysis.

The Forensic Engineering course teaches students skills beyond forensic investigations for legal proceedings. Similar investigations are pursued for product development, manufacturing, process control and research. OCCAM has also analysed product development issues involving the characterization of adhesion failures in laminates, component malfunction in electronic assemblies, identification of contaminants in high-value manufactured metals and the discovery of defects in multilayer optics.

“This new certificate will create a unique opportunity for students to gain specialized expertise and recognition for a personal and professional commitment to enhanced engineering investigation skills,” explains Perovic. “Learning how to think more logically is crucial for the development of good forensic engineering skills.”

—This article was originally published by U of T Engineering News and has been re-purposed with permission