One of the bigger challenges in designing advanced structural materials, such as bone-like medical implants and stronger parts for more fuel-efficient aircraft, is the length of time it takes for research to move from laboratories to industrial applications.

“Designing microstructures is a key step in materials development,” says Professor Yu Zou (MSE), whose lab group is using machine learning to accelerate the discovery of new structural materials.

“But traditional materials design, which is based on experiments or simulation methods, could take years — even decades — to identify the right microstructure.”

In a new paper, published in Materials Today, Zou’s team describes a novel end-to-end framework used to tailor the microstructure of Ti-6Al-4V, the most widely used titanium alloy in the aerospace and biomedical industries.

“This work could enable material scientists and engineers to discover microstructures at speeds unseen before, by simply inputting their desired mechanical properties into the framework,” says Xiao Shang (MSE PhD candidate), the lead author of the paper.

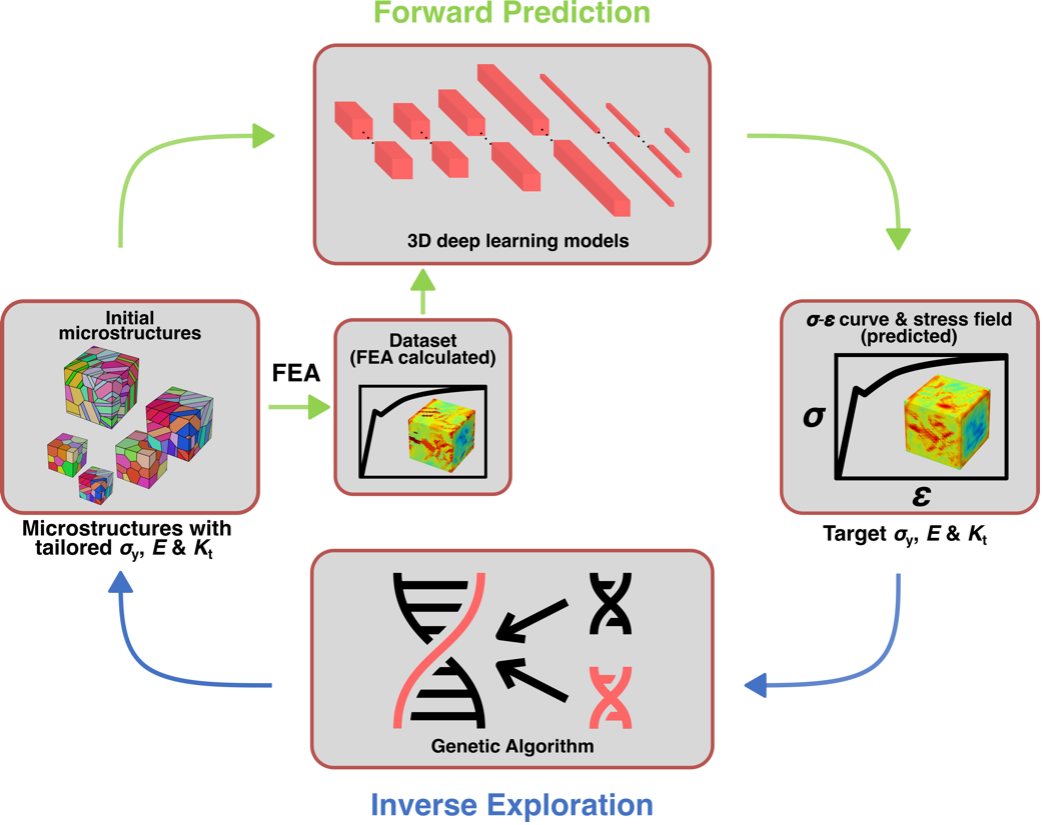

The researchers began by training two deep-learning models to accurately predict material properties from their microstructures. They then integrated a genetic algorithm with the deep-learning models to close the materials-by-design loop, which allows the framework to design optimal material microstructures with target mechanical properties.

“In less than eight hours, we identified titanium alloy microstructures that showed both the high strength and high stiffness needed to strengthen the structural components of airplanes,” says Shang.

“We also designed titanium alloys with the same chemical compositions as the former but with different microstructures that are about 15% more compliant for biomedical implants compatible with human bones.”

The researchers did face some bottlenecks during the development of their deep learning models. They had to generate their own dataset of close to 6,000 different microstructures through simulation, and they were able to acquire the massive computing powers that made the dataset generation possible by working with super computers at the Digital Research Alliance of Canada.

“We constantly ran into situations where our selected deep learning models and/or optimization algorithms just wouldn’t work as well as we expected,” says Shang.

“But we were patient and held on to our research plan, while actively searching for new approaches to make the models work.”

This past summer, the research, which is supported by the Data Sciences Institute and Centre for Analytics and Artificial Intelligence Engineering at U of T, won a Poster Prize at the 2023 Accelerate Conference.

“Looking forward, we want to further optimize and improve additive manufacturing technology so that they can continue to advance this new framework,” says Tianyi Lyu (MSE PhD candidate), who along with Jiahui Zhang (MSE PhD candidate), is a co-author of the new paper — both working on metal additive manufacturing.

“We are advancing the quality and reliability of metal additive manufacturing, unleashing its potentials to locally tailor the material microstructure during printing,” adds Zou.

“For example, with traditional technology, it is close to impossible to tailor biomedical materials for different patients. But we want to enable the future of personalized biomedical implants by making it possible to print the shape and mechanical properties that match a patient’s needs in only a few days.”