Undergraduate student Rachel Ghany and PhD candidate Paul Wu win top student research poster prizes at AISTech 2013

[sharexy]

Photo: MSE PhD candidate Paul Wu (left), and Year 4 Materials Engineering undergraduate student Rachel Ghany (MSE 1T3, right)

May 13, 2013

Congratulations to Rachel Ghany and Paul Wu for winning top prizes at this year’s Association for Iron & Steel Technology Conference & Exposition (AISTech) 2013 undergraduate and graduate student research competitions, respectively. Held annually, AISTech boasts one of the largest gatherings of materials engineering professionals in the iron and steel industries from around the globe. This year’s conference and exposition was held at the David L. Lawrence Convention Centre in Pittsburgh, PA, USA.

Ghany, a final year materials engineering undergraduate student, won the top prize in the Undergraduate Student Project Presentation Contest. Her presentation titled, “Removal of phosphorous, sulphur, and arsenic from ferronickel and nickel alloys by levitation refining,” was selected as one of eight finalists on the basis of abstracts submitted prior to the conference, and subsequently claimed the top prize in the contest.

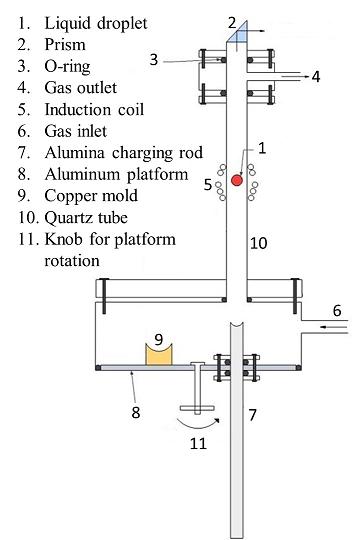

Ghany’s research, derived largely from her 4th year thesis project supervised by Professor Emeritus Alex McLean, involves the removal of unwanted impurities from a spent nickel alloy catalyst employed in the petroleum industry. Using an electromagnetic levitation technique previously developed by PhD candidate Paul Wu and senior research associate Dr. Yindong Yang, the successful removal of the impurities allows for the catalyst to be redeployed in the original petroleum process, or to be used in high-quality stainless steel manufacturing.

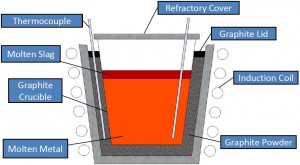

Wu, a PhD candidate also in Professor Emeritus Alex McLean’s Ferrous Metallurgy Research Group, won 2nd prize in the Graduate Student Poster Contest. His poster titled, “Refining of ferronickel and nickel alloy using the by-products of aluminum industry,” also investigates the removal of unwanted impurities from spent nickel alloy catalyst but via a chemical reaction, known as a “flux” technique. What was once waste by-product from the aluminum industry is used to compose the slag layer needed to create the flux for impurities separation from the nickel alloy. The results are similar to Ghany’s work: the renewed nickel alloy catalyst can then be redeployed in the original petroleum process, or be used in high-quality stainless steel manufacturing.

“This research work showcases the viability of recycling and redeploying materials that were once considered as waste, illustrating our ability to increase sustainability and cost-reduction efforts in the metallurgical processing industry,” said Professor Jun Nogami, Chair of the Department of Materials Science & Engineering. “Congratulations to both Rachel and Paul for their outstanding work, as well as to Alex for his fine research supervision and continued dedication to our students. The involvement, in particular of undergraduates, in this kind of research is a fine example of our efforts in training innovative new minds for a greener future.”