MARCH 18, 2024

Professor Yu Zou (MSE) has joined a collaborative effort with government and research institutions in Canada to advance the manufacturing processes crucial for the development of small modular reactors (SMRs).

SMRs, hailed as the future of nuclear energy, hold the promise of delivering affordable and environmentally friendly power to various sectors, including remote communities and heavy industries.

Zou’s research group has received new funding of $1.2 million over four years from the Natural Sciences and Engineering Research Council (NSERC) Alliance program and Natural Resources Canada.

“This new grant will support my group’s research activities in additive manufacturing and training next-generation leaders in advanced manufacturing for the nuclear sector in Canada,” says Zou.

The funding will drive research focused on developing innovative methods for efficient fabrication of SMR constructions. Zou’s team will leverage their expertise in materials science and mechanical engineering to lead the academic aspect of this collaborative endeavour.

Partnering with Natural Resources Canada’s CanmetMATERIALS, Canadian Nuclear Laboratories, and Kinectrics Inc. — organizations with extensive experience in nuclear materials and reactor technologies — will support a comprehensive approach to addressing the multifaceted challenges of SMR manufacturing.

The intricate design and operational requirements of SMRs necessitate innovative manufacturing techniques to ensure cost-effectiveness, reduced materials waste and streamlined fabrication processes, says Zou.

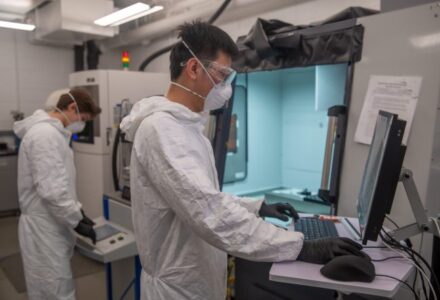

“At the heart of this initiative lies the integration of hybrid manufacturing, a cutting-edge approach that combines additive manufacturing and subtractive manufacturing processes,” he says.

“By harnessing the synergies of these techniques within a unified framework, we are aiming to unlock new levels of efficiency and flexibility in producing SMR components with intricate geometries and superior performance characteristics.”

The overarching objectives of this partnership will encompass three areas:

- The development and optimization of advanced manufacturing techniques through research and experimentation that will refine hybrid and additive manufacturing processes tailored specifically for SMR constructions.

- Supporting qualification of components, which is crucial to the success of SMRs. By adhering to stringent regulatory requirements, the consortium aims to ensure the safety, reliability and compliance of SMR components.

- Training the next generation through hands-on research opportunities, interdisciplinary collaboration and industry engagement aimed at propelling Canada’s nuclear industry forward.

“By making use of the collective expertise and resources of academia, government and industry, this collaborative research initiative will not only accelerate the advancement of SMR technology, but also positions Canada as a global leader in sustainable energy innovation,” says Zou.

“As the world strives to transition towards a carbon-neutral future, initiatives like this underscore the critical role of collaborative research in driving transformative change.”