Dr. Michael Helander, co-founder and CEO of OTI Lumionics, is working with his team to drive down the cost of organic light-emitting diode (OLED) lighting and display manufacturing through innovative materials and materials processing solutions. They are developing advanced materials—by design—using quantum simulations, machine learning and real-world testing in pilot production.

OTI Lumionics has developed a fast materials design approach, tailored to OLEDs and other electronic materials, that consists of a combination of machine learning techniques, computational chemistry simulations, optimization, rapid synthesis, and closed-loop feedback from testing of new materials in pilot production. They work with the largest electronics companies in the world to design new materials that are mass-production ready, enabling the next generation of exciting consumer electronics.

One application of OTI Lumionics materials, that has been designed using this approach, is in transparent displays, which will soon be available in smartphones, helping to hide the array of sensors and front-facing camera under the display. When you are “heads-up driving” – viewing your speedometer and mileage on the windshield of your car – you are looking at another application of this technology.

Instead of using a traditional approach to materials discovery which requires synthesizing and testing thousands of variations to find the suitable candidate, OTI Lumionics has developed software tools to simulate and predict the properties of new materials, allowing a larger pool of candidates to be screened than could otherwise be synthesized and tested. Thus, new materials that meet the precise requirements of the largest electronics manufacturers can be “designed” rather than discovered by chance.

“Quantum computing has the potential to revolutionize materials design, by enabling highly accurate simulations that could otherwise not be solved on classical hardware. Unfortunately, current gate-based quantum computing is far from being powerful enough to simulate commercial-sized problem,” said OTI Lumionics Head of Materials Discovery, Scott Genin.

Using Azure Quantum and quantum optimization solutions running on classical hardware, Quantum Inspired Optimization (QIO) can enable quantum methods for materials simulations that yield more accurate results.

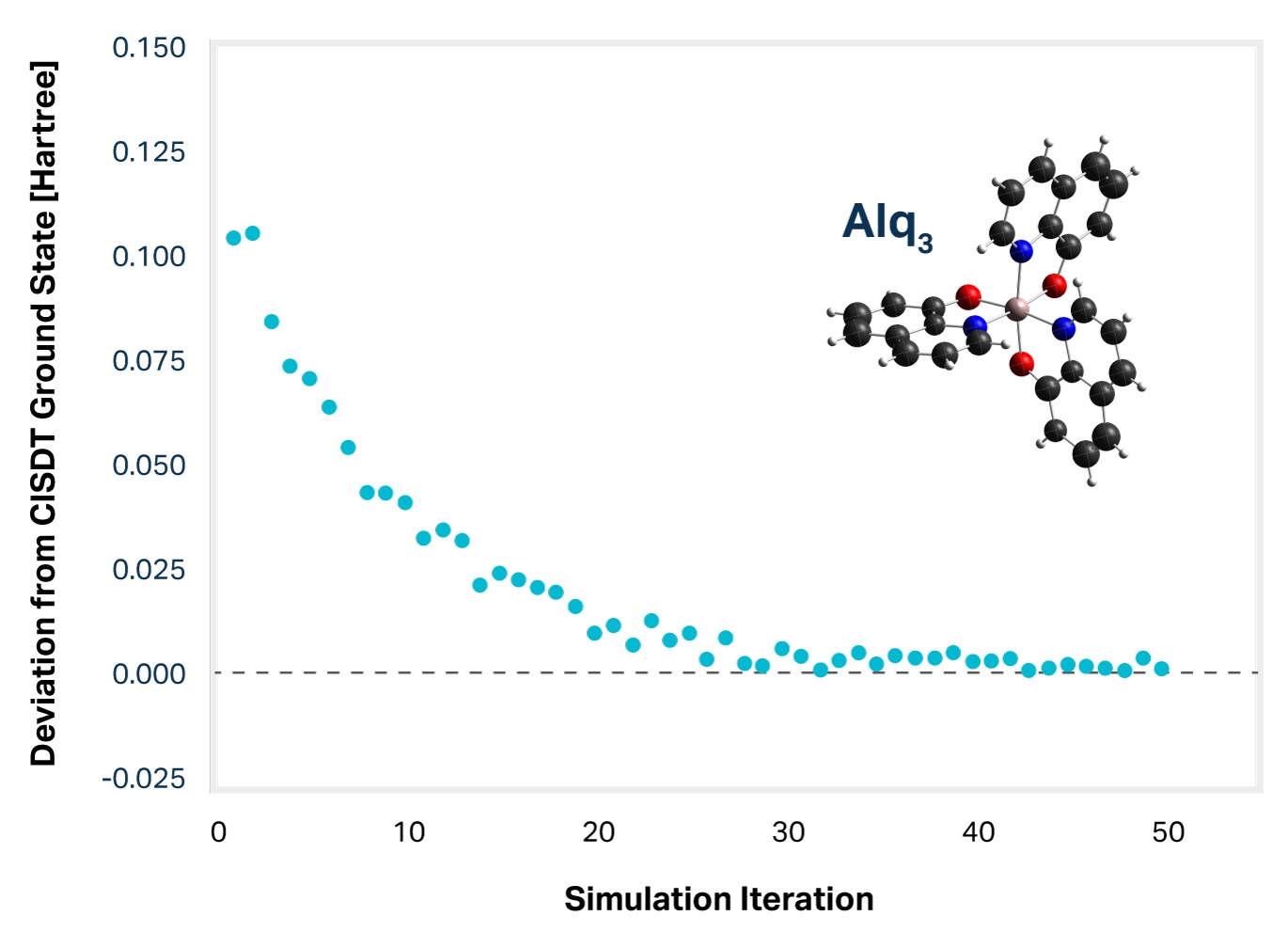

As an early adopter of quantum computing, OTI Lumionics has invested in a team of quantum chemists, computer scientists, and software engineers to develop their own quantum computing algorithms and software for materials design, and have made significant theoretical and practical advances in the field. With their algorithms now running on Azure Quantum, OTI Lumionics is able to demonstrate meaningful results on commercially relevant sized problems, today. For example, by using Azure Quantum’s optimization tools in their pipeline, OTI Lumionics successfully performed a complete active space configuration interaction simulation of an archetype green light emitting OLED material – Alq3 [Tris (8-hydroxyquinolinato) aluminum].

“We have designed our solver platform in Azure Quantum with customers in mind,” said Microsoft Principal Research Manager, Helmut Katzgraber. “Our quantum solutions on classical hardware do not have the limitations of other solvers and optimization hardware and are driven by some of the most powerful algorithms currently available, while being easy to use as there is no need to tune parameters. “

To give you an idea of the computational savings the same simulation of Alq3 would require 42 error-corrected qubits on gate-based quantum hardware. Mapping the problem to an industry-standard quadratic unconstrained binary optimization (QUBO) using OTI Lumionics reparametrization would require a quantum annealer (or QUBO solver) that could handle 58,265 variables. Solving a QUBO problem with this many variables is intractable, and even an equivalent simulation of Alq3 using standard classical computational chemistry software would require a supercomputer. In contrast, using Azure Quantum, the higher-order binary problem can be handled natively, meaning that this problem only requires 132 variables on classical hardware to perform the simulation.

“The fact is that we have compelling results that show that we can start using quantum solutions for commercial problems in a matter of months, not years,” said OTI Lumionics Co-founder and CEO, Michael Helander. “Using Azure Quantum, we now have the potential to dramatically increase the accuracy and throughput of the computational chemistry simulations that underpin our entire materials design workflow.”

Using Azure Quantum, OTI Lumionics can open their computational pipeline to run more accurate simulations at significantly higher speeds, which could ultimately lead to timelier and lower cost materials design, and thus better OLED displays.