World’s most efficient OLED on plastic built at U of T

Photo (left): Helander, Wang and Lu’s flexible OLED on plastic

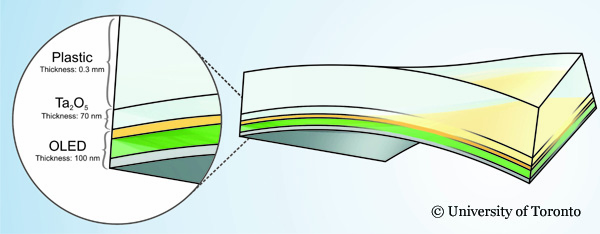

Photo (right): schematic of Helander, Wang and Lu’s flexible OLED illustrating the various nano-layer components

October 31, 2011

University of Toronto materials science and engineering researchers have developed the world’s most efficient organic light-emitting diodes (OLEDs) on plastic. This result enables a flexible form factor, not to mention a less costly, alternative to traditional OLED manufacturing, which currently relies on rigid glass.

The results are reported online in the latest issue of Nature Photonics.

OLEDs provide high-contrast and low-energy displays that are rapidly becoming the dominant technology for advanced electronic screens. They are already used in some cell phone and other smaller-scale applications.

Current state-of-the-art OLEDs are produced using heavy-metal doped glass in order to achieve high efficiency and brightness, which makes them expensive to manufacture, heavy, rigid and fragile.

“For years, the biggest excitement behind OLED technologies has been the potential to effectively produce them on flexible plastic,” says U of T Materials Science & Engineering professor Zheng-Hong Lu, Canada Research Chair in Organic Optoelectronics. “Using plastic can substantially reduce the cost of production, while providing designers with a more durable and flexible material to use in their products.”

Using plastic can substantially reduce the cost of production, while providing designers with a more durable and flexible material to use in their products.

Photo: doctoral researchers Michael G. Helander (left) and Zhibin Wang (right) with Professor Zheng-Hong Lu (centre) on the cover of Impact, Vol. II

The research, which was supervised by Professor Lu and led by PhD candidates Zhibin Wang and Michael G. Helander, demonstrated the first high-efficiency OLED on plastic. The performance of their device is comparable with the best glass-based OLEDs, while providing the benefits offered by using plastic.

Wang and Helander were able to re-construct the high-refractive index property previously limited to heavy metal-doped glass by using a 50-100 nanometre (nm) thick layer of tantalum(V) oxide (Ta2O5), an advanced optical thin-film coating material. This advanced coating technique, when applied on flexible plastic, allowed the team to build the highest-efficiency OLED device ever reported with a glass-free design.

“This discovery, unlocks the full potential of OLEDs, leading the way to energy-efficient, flexible and impact-resistant displays,” says Professor Lu.